Вы знаете, что такое зазор экструзии?

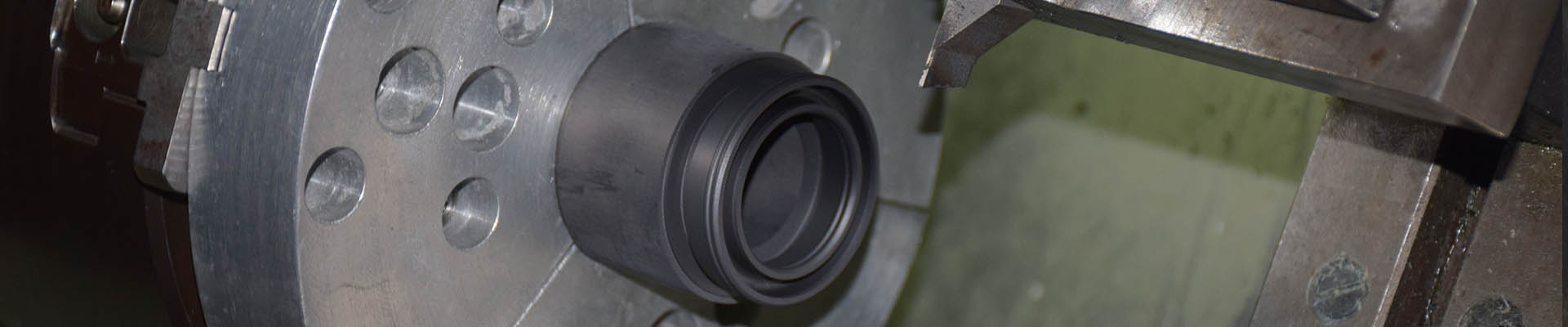

Зазор экструзии — это пространство между двумя сопрягаемыми поверхностями в системе уплотнения, обычно между уплотнением и крепежными элементами (например, поршнем и цилиндром, или штоком и сальником), где установлено уплотнение. Под давлением материал уплотнения может стремиться вытечь или «экструзироваться» в этот зазор, что со временем может привести к повреждению уплотнения, снижению его производительности или выходу из строя. Зазор экструзии является критически важным геометрическим параметром в конструкции уплотнения, поскольку его размер напрямую влияет на способность уплотнения сопротивляться деформации и поддерживать эффективный барьер против утечки жидкости или газа.

Сопротивление уплотнения выдавливанию определяется сочетанием свойств материала, конструктивных факторов и условий эксплуатации, включая:

1. Твердость и эластичность материала: Более мягкие материалы (с более низким показателем твердости по дюрометру) более склонны к выдавливанию, в то время как более твердые материалы (с более высоким показателем твердости по дюрометру) обычно обладают лучшей устойчивостью. Однако чрезмерная твердость может ухудшить герметичность, поэтому необходим баланс. Эластичность (способность возвращаться к исходной форме после деформации) также играет роль — материалы с высокой эластичностью лучше восстанавливаются после временного выдавливания под воздействием циклов давления.

2. Прочность материала и сопротивление разрыву: Полимеры с более высокой прочностью на разрыв и сопротивлением разрыву с меньшей вероятностью разорвутся или деформируются необратимо при продавливании в экструзионном зазоре. Армирующие добавки (например, ткани или волокна) могут улучшить эти свойства, особенно в динамических герметизирующих процессах.

3. Особенности конструкции уплотнения:

о Резервные кольца Это жесткие или полужесткие компоненты, расположенные рядом с уплотнением для физического блокирования экструзионного зазора, предотвращающего попадание уплотнительного материала в него под высоким давлением.

Геометрия уплотнения: Профили с прочным поперечным сечением (например, U-образные чашки, V-образные кольца или специально сформированные кромки) более равномерно распределяют давление и снижают концентрацию напряжений в месте соединения.

o Скошенные края или перепады высоты: предназначены для минимизации контакта уплотнения с зазором путем направления материала внутрь под давлением, что уменьшает склонность к выдавливанию.

4. Размер зазора экструзии: Меньший зазор по своей природе ограничивает пространство, доступное для экструзии, что повышает сопротивление. На размер зазора влияют производственные допуски сопрягаемых деталей (например, диаметр цилиндра или штока) и выравнивание сборки.

5. Рабочее давление: Более высокое давление увеличивает усилие, выталкивающее уплотнительный материал в зазор, ускоряя экструзию. Уплотнения должны быть рассчитаны на максимальное давление в системе, часто с дополнительными кольцами, необходимыми для работы в условиях высокого давления (обычно выше 10–15 МПа, в зависимости от материала).

6. Температура: Повышенные температуры размягчают уплотнительные материалы, снижая их жесткость и сопротивление экструзии. Для поддержания механической целостности в условиях высоких температур необходимы материалы с высокой термостойкостью (например, фторполимеры, такие как ПТФЭ, или перфторэластомеры).

7. Динамические и статические приложения: Динамические уплотнения (например, поршневые или штоковые уплотнения При возвратно-поступательном движении уплотнения испытывают дополнительное трение и износ, что со временем может привести к ухудшению его структуры и повысить вероятность экструзии по сравнению со статическими уплотнениями.

8. Совместимость с жидкостями: Несовместимые жидкости (например, агрессивные химикаты, масла или растворители) могут вызывать набухание, разрушение или пластификацию материала уплотнения, ослабляя его механические свойства и снижая сопротивление экструзии.

Зазор между уплотнителями и кольцами — это не просто конструктивный выбор; он имеет фундаментальное значение для работы уплотнений и уплотнительных колец в условиях высокого давления. Выбирая подходящие материалы, оптимизируя допуски крепежных элементов и используя передовые конструктивные решения, такие как удлиненные уплотнительные кромки и опорные кольца, инженеры могут значительно повысить надежность и срок службы уплотнений.

В JST Мы специализируемся на разработке высокоэффективных уплотнений для самых сложных задач. Независимо от того, связан ли ваш проект с нефтегазовой отраслью, строительной техникой, медицинским оборудованием, полупроводниковой промышленностью или автомобилями на новых источниках энергии, наша инженерная команда разработает решения, обеспечивающие исключительную производительность и долговечность.

Свяжитесь с нами сегодня, чтобы обсудить ваши уникальные задачи по герметизации и узнать, как мы можем разработать идеальное решение для ваших потребностей.

Новый блог

© Авторские права: 2026 Guangzhou JST Seals Technology Co., Ltd. Все права защищены.

Сканировать в WeChat