Технический обзор: Износостойкие кольца из ПТФЭ (направляющие кольца) в гидравлических системах

1. Сценарии применения

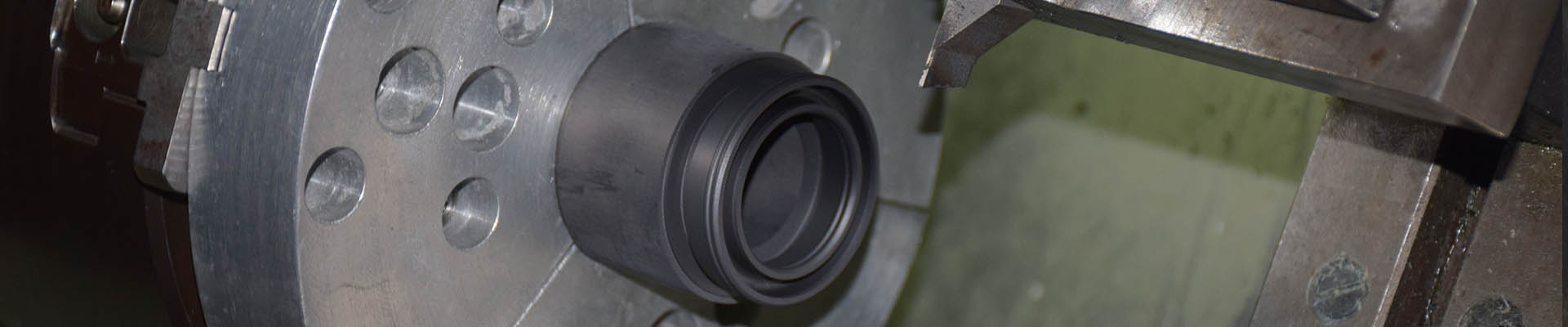

Износостойкие кольца из ПТФЭ (политетрафторэтилена)

также известный как

направляющие кольца

,

В основном используются в гидравлических цилиндрах и поршнях для:

Предоставьте рекомендации: Расположите шток поршня по центру цилиндра, а поршень — по центру трубки, предотвращая контакт металла с металлом и смещение.

Поглощение радиальных нагрузок: Учитывайте боковые нагрузки и поперечные силы, действующие на шток или поршень поршня.

Снижение трения: Обеспечивает плавное возвратно-поступательное движение с низким коэффициентом трения под высоким давлением.

Типичные варианты монтажа: Расположен с обеих сторон поршня и внутри сальника/втулки шатуна.

2. Ключевые преимущества

Исключительно низкое трение: Самый низкий коэффициент трения среди распространенных полимеров, что обеспечивает высокую эффективность и плавное движение даже при запуске (отсутствие эффекта «залипания-проскальзывания»).

Превосходная химическая стойкость: Инертен практически ко всем гидравлическим жидкостям, химическим веществам и растворителям.

Широкий температурный диапазон: Подходит для непрерывного использования при температурах приблизительно от -200°C до +260°C.

Низкий износ и длительный срок службы: Обладает превосходной износостойкостью, защищая сопрягаемые металлические поверхности.

Возможность "сухого" запуска: Может временно работать без смазки, подходит для применений, где смазка минимальна или нежелательна.

3. Ограничения и неподходящие условия

Износостойкие кольца из ПТФЭ могут быть НЕ оптимальным выбором в следующих случаях:

Высокие нагрузки при низких скоростях (холодный поток): При высоких непрерывных радиальных нагрузках, особенно на низких скоростях, чистый ПТФЭ может подвергаться «холодному течению» (ползучести), что приводит к деформации и потере герметичности/направляющих свойств.

Области применения, требующие высокой механической прочности/жесткости: Чистый ПТФЭ относительно мягкий и обладает низкой механической прочностью по сравнению с такими материалами, как ПОМ или фенол. Он может быть непригоден для применений с чрезвычайно высокими динамическими нагрузками или там, где требуется высокая жесткость кольца.

Приложения, чувствительные к стоимости: Высокоэффективные компаунды на основе ПТФЭ (часто наполненные бронзой, стекловолокном, углеродом и т. д. для улучшения сопротивления текучести при низких температурах и износостойкости) обычно дороже, чем стандартные полимерные аналоги, такие как полиуретан или нейлон.

Высокая износостойкость имеет первостепенное значение в условиях загрязненной среды: Хотя ПТФЭ обладает хорошими износостойкими характеристиками, в условиях сильного абразивного воздействия (например, при загрязнении твердыми частицами) специально разработанные полиуретановые или термопластичные полиэфирные (ПЭТФ) материалы могут обеспечить более высокую износостойкость.

Сверхвысокое давление с экстремальными краевыми нагрузками: необходимы особые меры предосторожности и проектные решения, поскольку экстремальные локальные давления могут превышать предел прочности материала на сжатие.

Износостойкие кольца из ПТФЭ превосходно подходят для применений, требующих сверхнизкого трения, широкого температурного диапазона и химической совместимости. Их использование следует тщательно оценивать с учетом нагрузки, скорости, условий окружающей среды и стоимости, при этом часто выбираются наполненные ПТФЭ компаунды для смягчения ограничений, связанных с низкой текучестью.

Новый блог

© Авторские права: 2026 Guangzhou JST Seals Technology Co., Ltd. Все права защищены.

Сканировать в WeChat